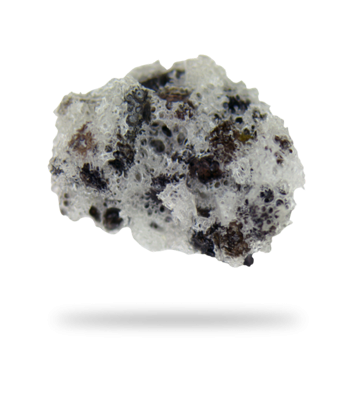

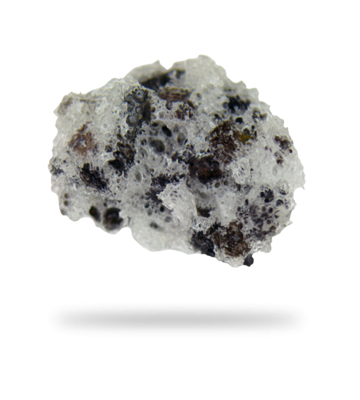

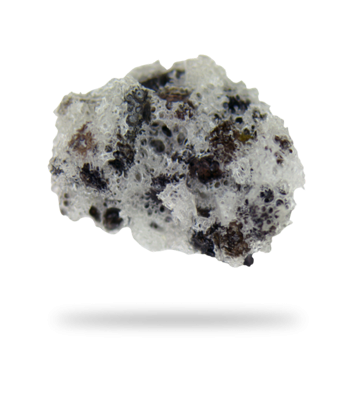

Sponge-Jet SuperMedia™ SpongeMedia™

Shipping

Business orders?

Business orders?

You can easily place business orders at Reemster. On the cart page, select "business" and automatically enjoy the following benefits:

- Fast delivery: Quick and reliable shipping with track & trace.

- Personal service: Access to our business customer service.

- Volume discount: Discounts on bulk orders are automatically applied to your cart.

- Invoice: Clear and itemized VAT invoice, optionally with your own reference number.

- VAT reverse charge: Do you have a VAT number? Enter your VAT number on the cart page. Our systems will verify the VAT number and apply 0% VAT at checkout if the number is valid.

Questions about business orders? Contact us.

The SpongeMedia™ is designed to remove coatings or contaminants in a very aggressive way and gives a very high profile on both steel and concrete. The extreme surface roughness that this sponge creates, although too large for most coatings, is well suited for the preparation or removal of elastomer and rubber coatings and for the removal of hazardous substances for remediation or pre-decommissioning purposes. The product effectively removes 6 mm of concrete at a rate of 11m² per hour - leaving behind an ICRI CSP-7 profile. Blasting with SuperMedia™ is an effective preparation of concrete prior to coating - including the application of fire-resistant coatings.

PackagingThe SpongeMedia™ is packed in loose bags. When ordering 3 or more bags, these are placed on a pallet. We can place up to 70 bags of SpongeMedia™ on a pallet.

About Sponge-JetSponge-Jet is an alternative to conventional blasting. The product is produced by Sponge-Jet Inc, an American company. The Media is manufactured in accordance with the latest standards (SSPC-AB4) and is ISO 9001 certified. The power of the system is the patented SpongeMedia™ blasting agent. It consists of two components. An artificial (polyurethane) sponge serves as a carrier for a blasting agent, such as aluminum oxide or glass beads. A Sponge-Jet Feed Unit (blast pot) drives the SpongeMedia™ abrasives to a surface using compressed air. Via a centralized control panel, the blasting pressure and media delivery speed can be adjusted so that the desired (accurate) result can be achieved. The sponge is crushed at impact and then cleans or rubs the surface using the impregnated blasting agent. The sponge then expands, which creates a vacuum, so that the detached coatings and contaminants are collected. The SpongeMedia™ can absorb up to 95% of the released waste material and significantly reduces the formation of (fine) dust and harmful emissions. The weighted sponge has almost no kinetic energy left and falls into the immediate vicinity. Because there is much less dust development, the user can clearly follow his progress and protective measures, such as personal protective equipment, can be made lighter.

For more information on abrasive blasting with Sponge-Jet, visit spongeblasting.com.

Note: In order to use Sponge-Jet blasting agents, you need an associated Sponge-Jet Feed Unit (blast pot).

-

ClassificationStandard

-

ApplicationBlasting - Aggressive

-

Intensity

-

Weight

Payment methods

Secure payment including